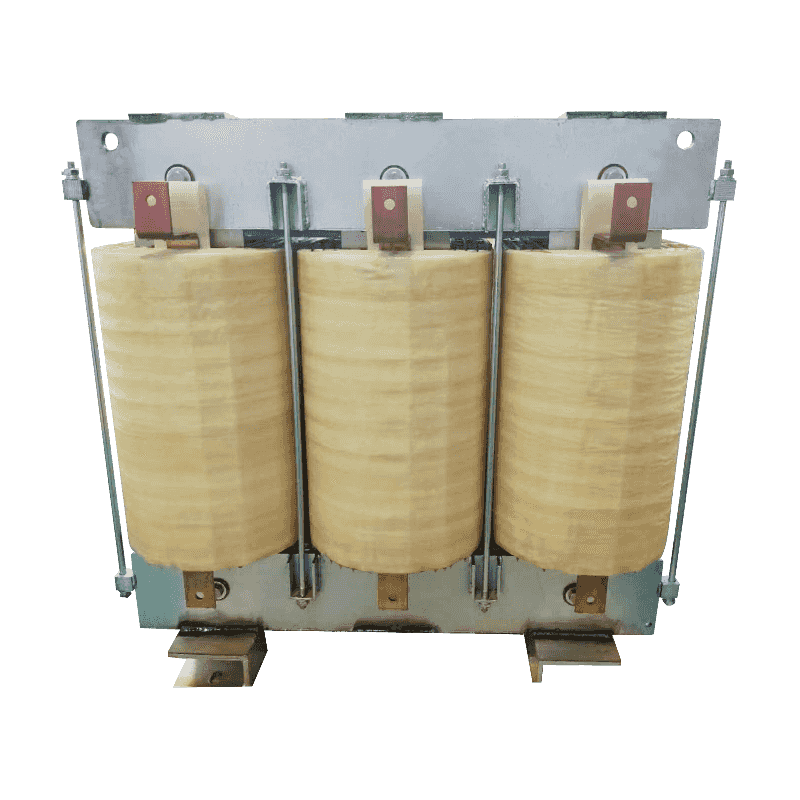

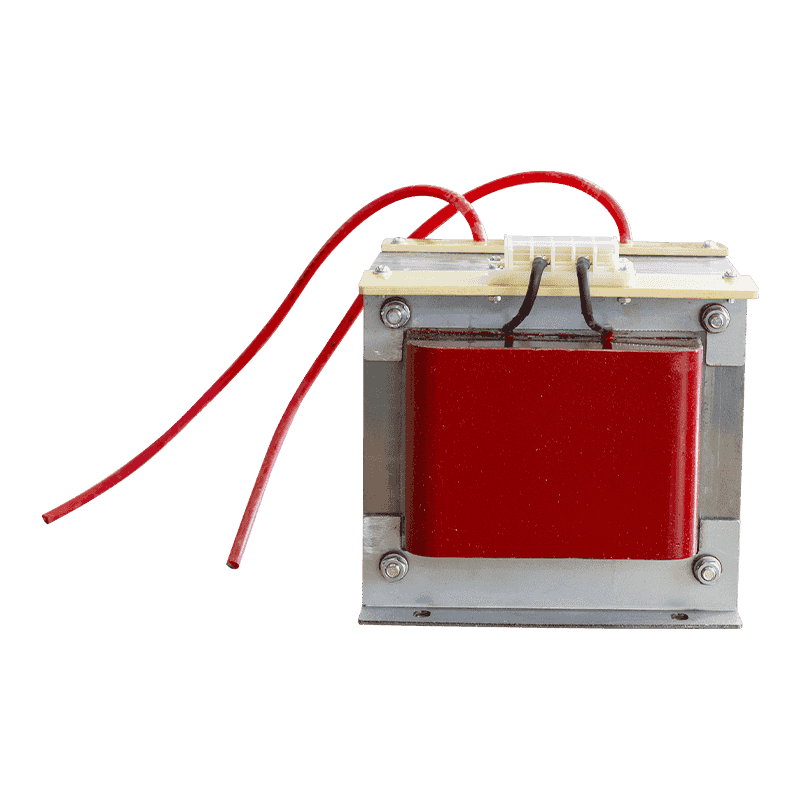

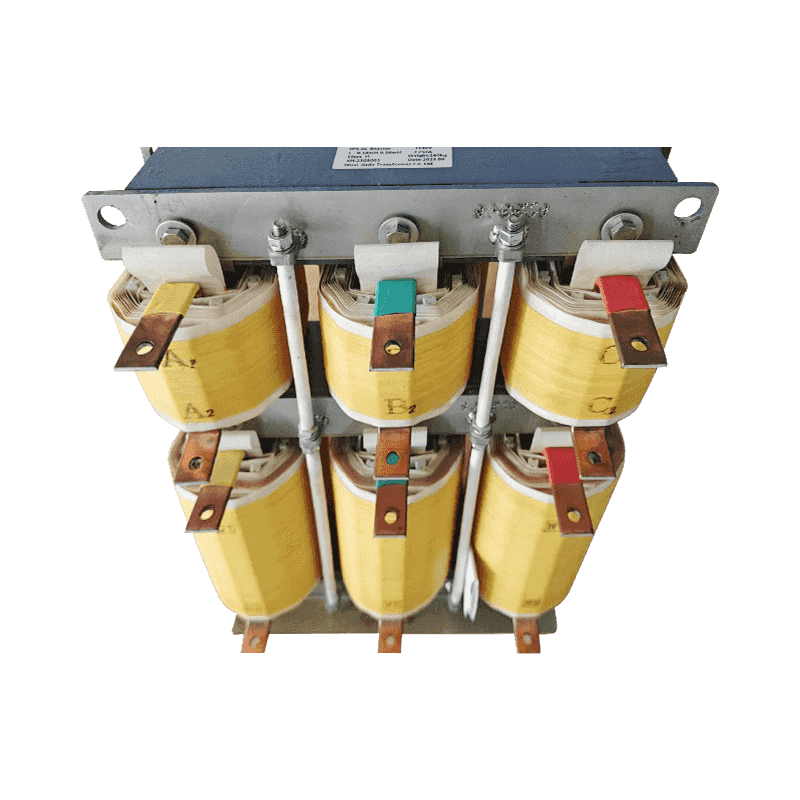

In the field of power engineering, the insulation performance of load reactors is one of the key factors for their stable operation and long life. In order to achieve this goal, vacuum impregnation technology emerged as the times require, and has gradually become an important process method to improve the insulation performance of reactors. The scientific principles and practical applications of this technology will be discussed in depth from aspects such as the creation of a vacuum state, the penetration mechanism of insulating paint and its impact on the insulation performance of reactors.

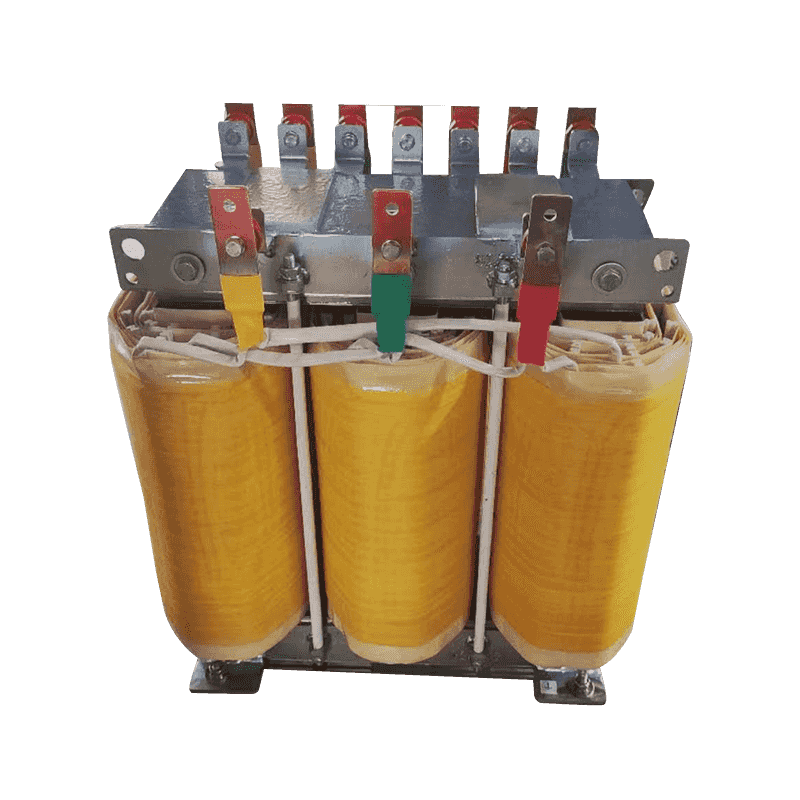

The creation of a vacuum state is the core premise of vacuum dipping technology. In a vacuum environment, all air molecules and residual gases are effectively eliminated, forming a nearly resistance-free space. This special environment is crucial to the penetration process of insulating paint because it eliminates air resistance and the possibility of bubble formation, providing favorable conditions for the deep penetration of insulating paint.

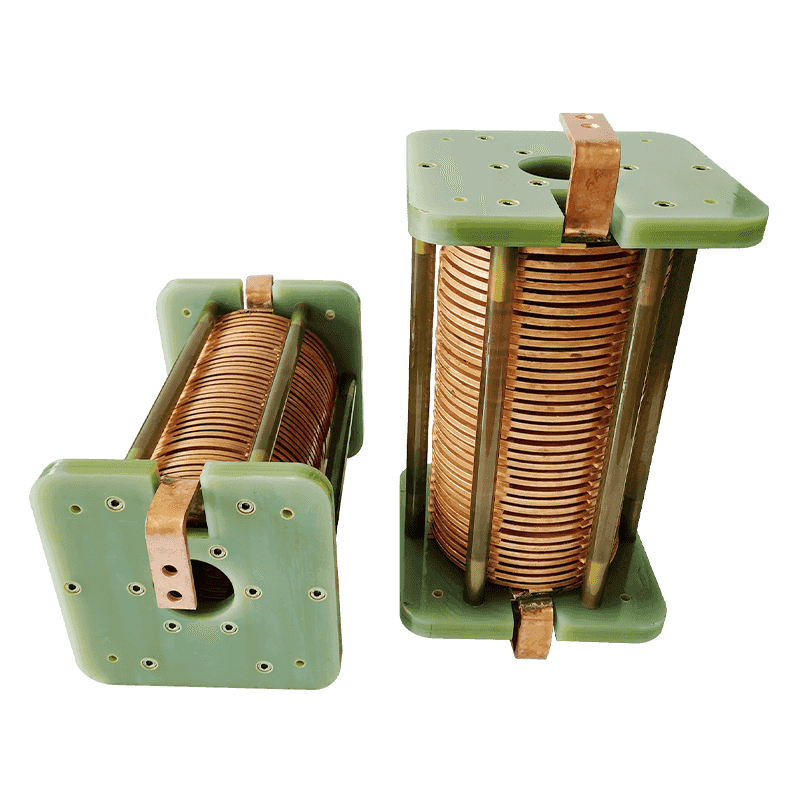

Under the influence of negative pressure, the behavior of the insulating paint changes significantly. In traditional environments, insulating paint is limited by surface tension and air resistance, making it difficult to fully penetrate into the tiny gaps and complex structures of reactors. However, in a vacuum state, these resistances are greatly weakened or even eliminated, allowing the insulating paint to easily overcome obstacles and penetrate deep into every corner of the reactor.

This deep penetration is not only reflected on the surface of the reactor, but more importantly, a dense insulation layer is also formed in the internal structure. Insulating paint fills all possible voids and cracks, creating a continuous and strong insulation network. The existence of this network greatly enhances the overall insulation performance of the reactor and provides a solid guarantee for the stable operation of the power system.

The deep penetration effect brought by vacuum impregnation technology has a significant impact on the insulation performance of the reactor. First of all, the increase in the thickness of the insulation layer directly improves the voltage resistance of the reactor and reduces the risk of insulation breakdown caused by high voltage. Secondly, the formation of an internal dense insulation network effectively prevents current leakage and short-circuit phenomena, improving the operational reliability and safety of the reactor.

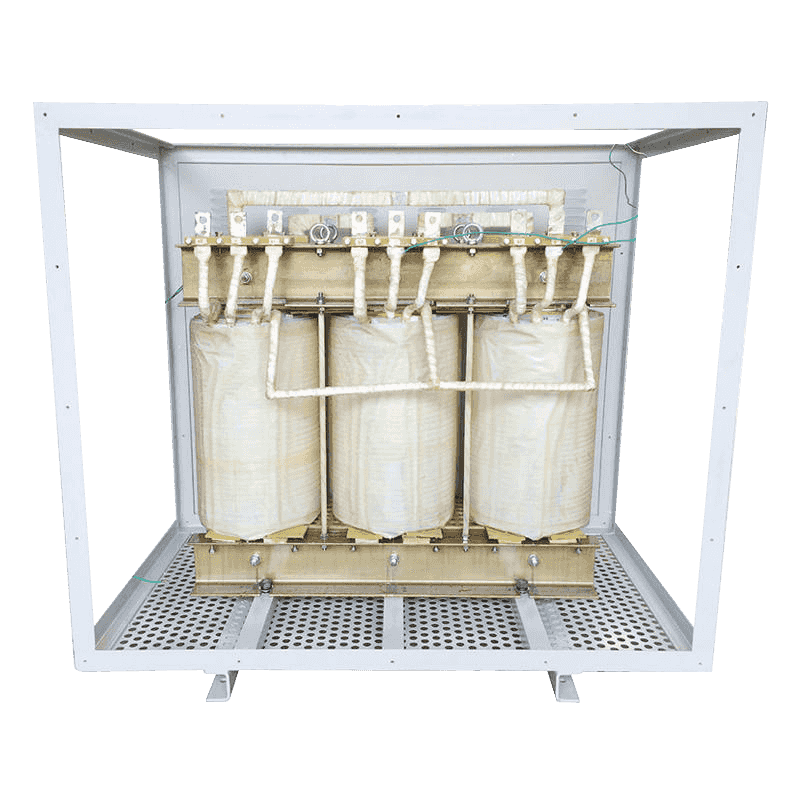

In addition, this technology also helps reduce the insulation aging rate caused by environmental factors (such as humidity, temperature changes, etc.) during the operation of the reactor. The dense insulation layer can effectively block the intrusion of external moisture and the corrosion of harmful gases, thereby extending the service life of the reactor.

Vacuum impregnation technology plays an important role in the manufacturing process of load reactors due to its unique penetration mechanism and significant insulation improvement effect. By creating a vacuum state and making full use of the penetration characteristics of insulating paint under negative pressure, this technology successfully builds a dense insulation network inside the reactor, effectively improving its insulation performance and durability. With the continuous development and progress of power engineering technology, we have reason to believe that vacuum impregnation technology will play a more important role in the future and promote technological innovation and development in related fields.

Eng

Eng  Español

Español

Contact Us