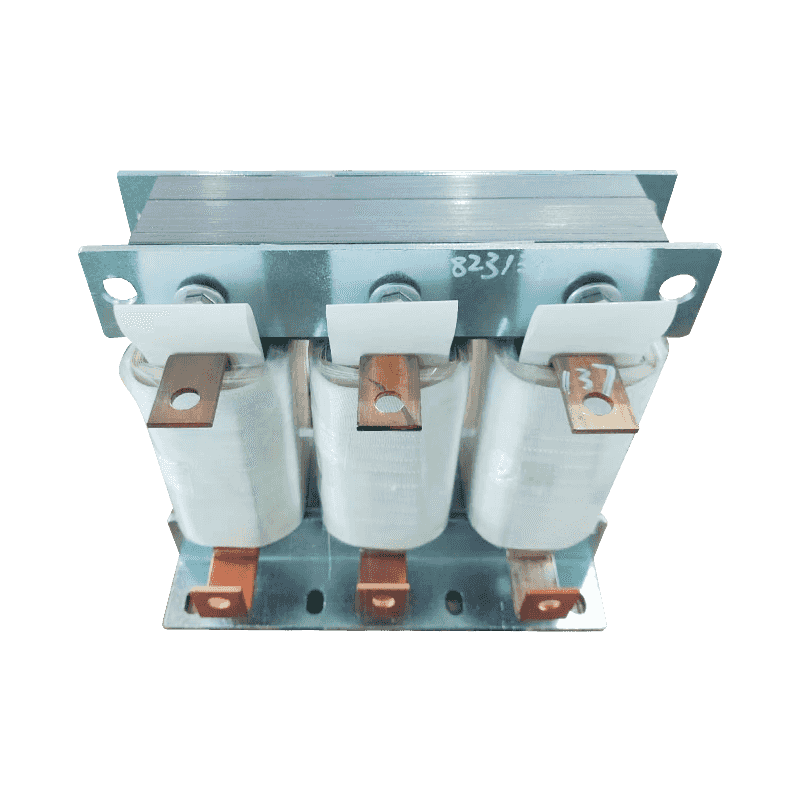

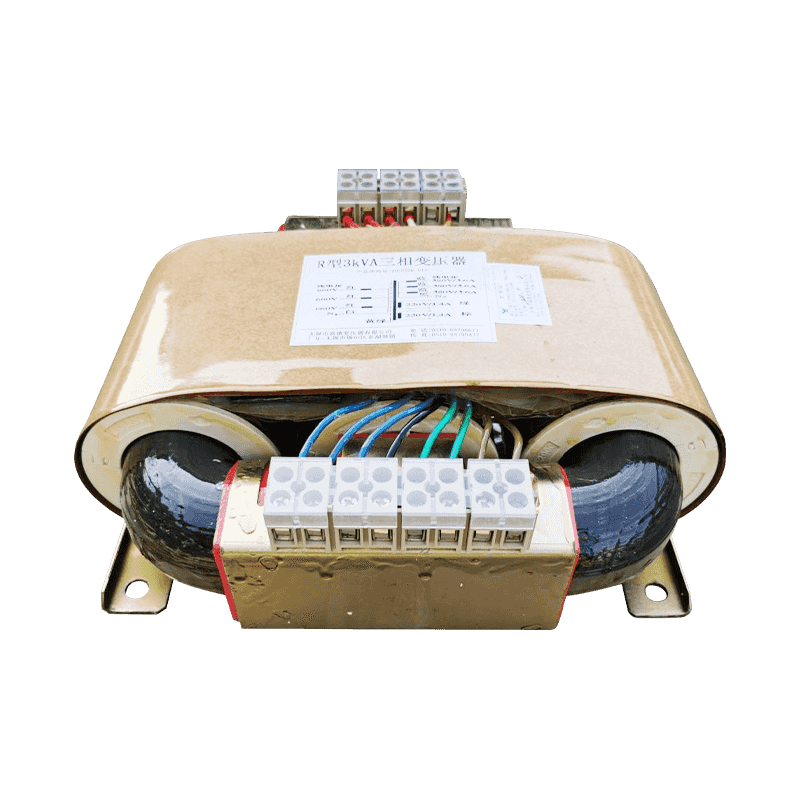

In the huge power system, filter reactors are an indispensable component, and their stable operation is directly related to the overall performance and safety of the power grid. Especially in high-voltage environments, the insulation structure design of filter reactors is particularly important. In-depth discussion of the insulation design requirements, technical challenges and solutions of filter reactors under high-voltage conditions to demonstrate their key role in ensuring the safety and stability of power systems.

Insulation challenges under high-voltage environments

Due to their special filtering functions, filter reactors in power systems are often deployed on lines with higher voltage levels. In such a working environment, filter reactors not only need to withstand normal rated voltages, but may also face extreme conditions such as transient overvoltages and operating overvoltages. Therefore, the design of its insulation structure must meet extremely high standards to ensure that the electrical connection between live parts and ground potential or parts with different potentials can be effectively isolated under any circumstances to prevent breakdown or flashover, thereby avoiding the serious consequences of short-circuit accidents.

Key elements of insulation structure design

Material selection

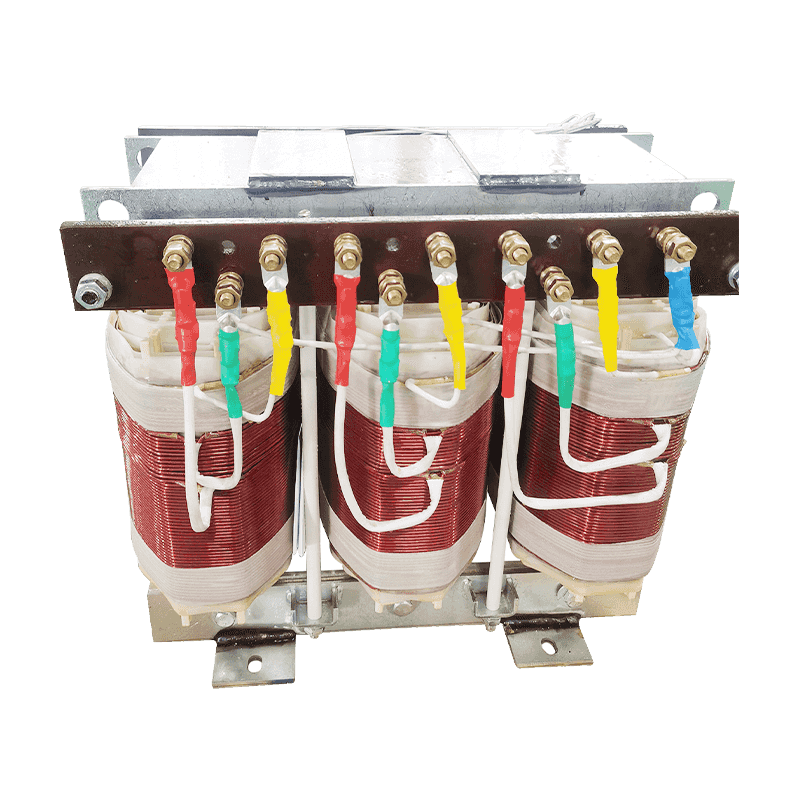

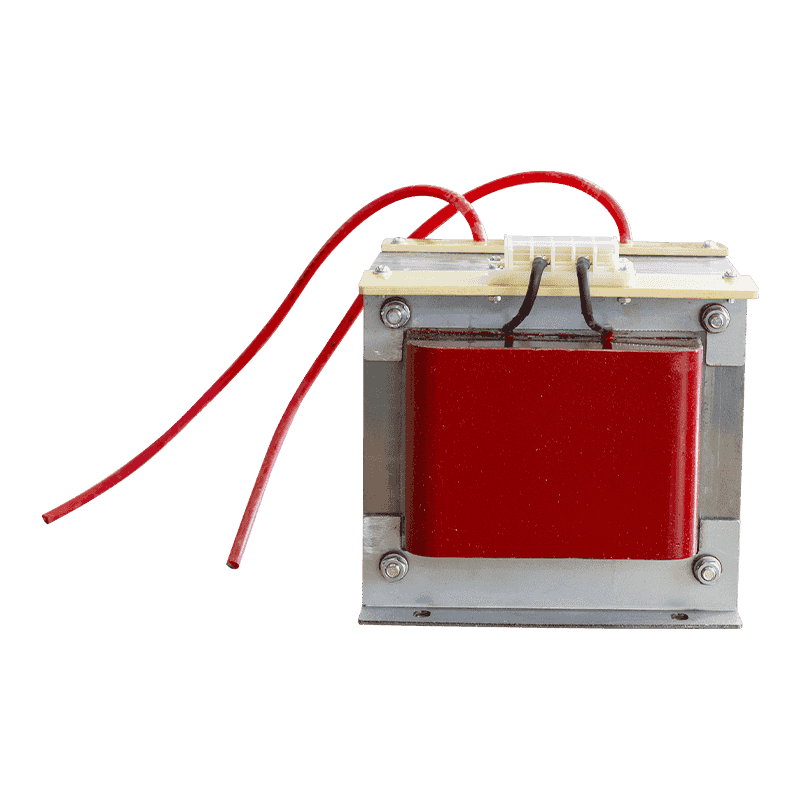

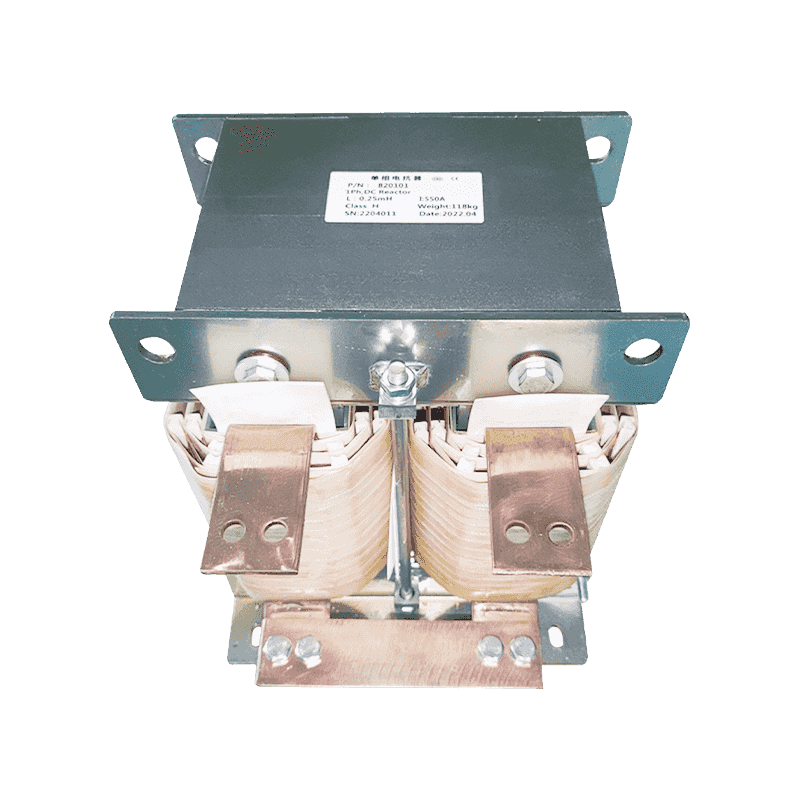

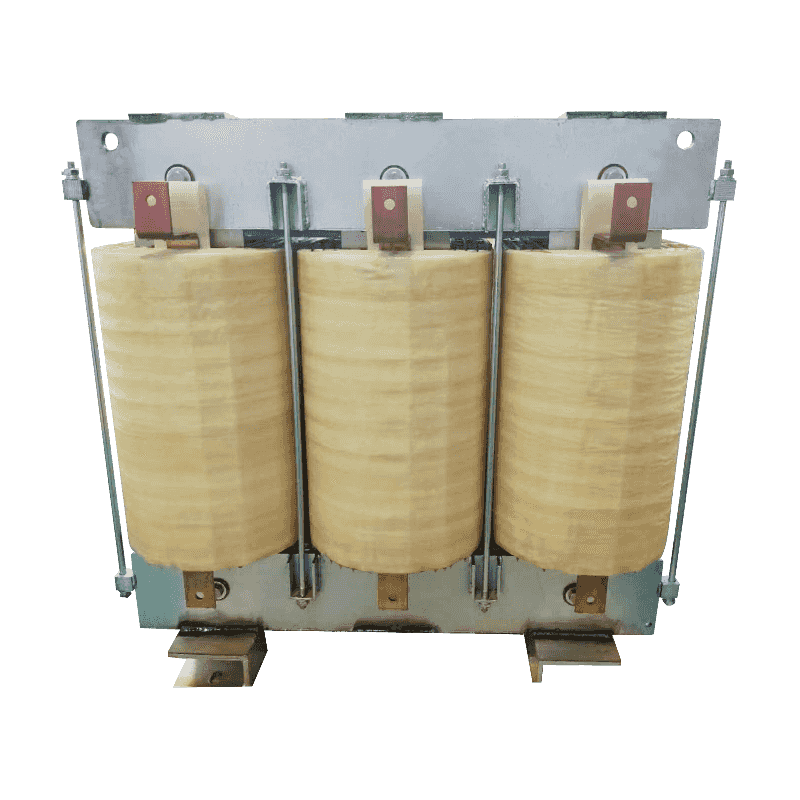

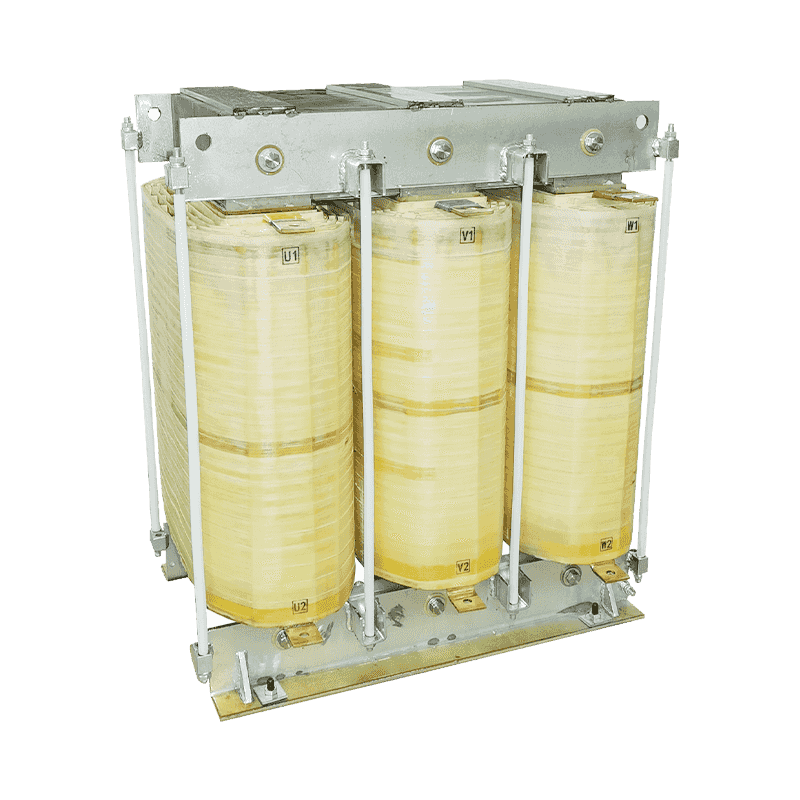

The selection of insulating materials is the basis of insulation structure design. High-quality insulating materials should have the characteristics of high dielectric strength, low dielectric loss, good heat resistance, chemical corrosion resistance and mechanical strength. Common insulating materials include epoxy resin, silicone rubber, ceramics, etc. According to the working conditions and design requirements of the filter reactor, the rational selection and optimization of these materials is the key to building a reliable insulation structure.

Structural layout

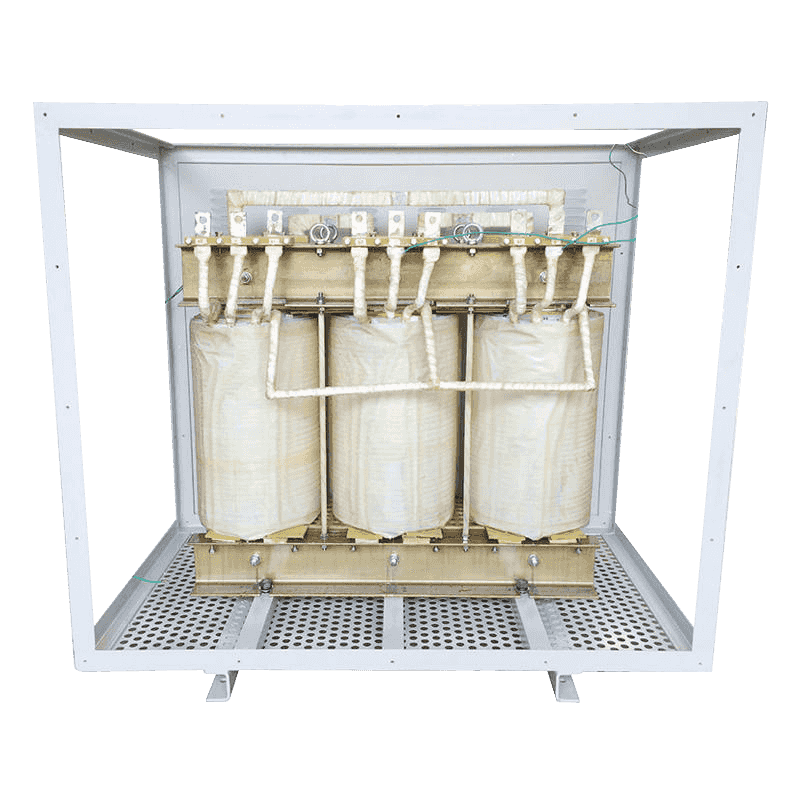

The layout of the insulation structure is directly related to its electrical performance and mechanical strength. When designing, factors such as electric field distribution, heat conduction path and mechanical stress need to be fully considered. Through reasonable structural layout, such as increasing the thickness of the insulation layer, adopting a multi-layer insulation structure, and setting a barrier layer, the insulation strength can be effectively improved and the risk of breakdown can be reduced.

Manufacturing process

The manufacturing process also has an important impact on the performance of the insulation structure. During the manufacturing process, process parameters such as temperature, pressure, and time need to be strictly controlled to ensure that the insulation material is fully cured, free of bubbles, cracks and other defects. At the same time, the finished product needs to be strictly tested for electrical performance and mechanical strength to ensure that it meets the design requirements.

Technical challenges and solutions

Partial discharge problem under high voltage

Under high voltage, partial discharge may occur inside or on the surface of the insulation structure, which may lead to a decrease in insulation performance or even breakdown. To solve this problem, the partial discharge resistance of the insulation material can be improved by adding nanofillers and optimizing the insulation material formula; at the same time, the electric field concentration and the occurrence of partial discharge can be reduced by improving the structural layout and manufacturing process.

Thermal stability problem

Under long-term high-load operation, the filter reactor will generate a lot of heat. If the insulation structure cannot effectively dissipate heat, it will lead to temperature rise and reduced insulation performance. Therefore, the heat conduction path and heat dissipation measures must be fully considered in the design of the insulation structure; at the same time, the selection of high-temperature resistant insulation materials is also an important means to solve the problem of thermal stability.

Adaptability under complex working conditions

The working conditions in the power system are complex and changeable, and the filter reactor may be affected by a variety of adverse factors such as lightning strikes, dirt accumulation, and mechanical vibration. Therefore, when designing the insulation structure, its adaptability to these complex working conditions must also be considered. By enhancing the weather resistance, anti-pollution ability and mechanical strength of the insulation structure, the operating reliability of the filter reactor under complex working conditions can be improved.

When the filter reactor is subjected to high voltage in the power system, its insulation structure design is crucial. By selecting high-quality insulation materials, optimizing the structural layout and manufacturing process, and solving technical challenges, a reliable insulation structure can be constructed to ensure the stable operation of the filter reactor under high voltage. In the future, with the continuous development of power technology and the continuous improvement of application needs, the insulation structure design of the filter reactor will also continue to innovate and improve, providing a more solid guarantee for the safe and stable operation of the power system.

Eng

Eng  Español

Español

Contact Us