DC reactors, also known as flat wave reactors, are used on the DC side of converters, general purpose inverters. The reactor has a DC with an AC component flowing through it. Its main purpose is to limit the AC component superimposed on the DC to a specified value, keep the rectifier current continuous, reduce the current pulsation value, improve the input power factor, and inhibit the harmonics generated by the converter.

Features:

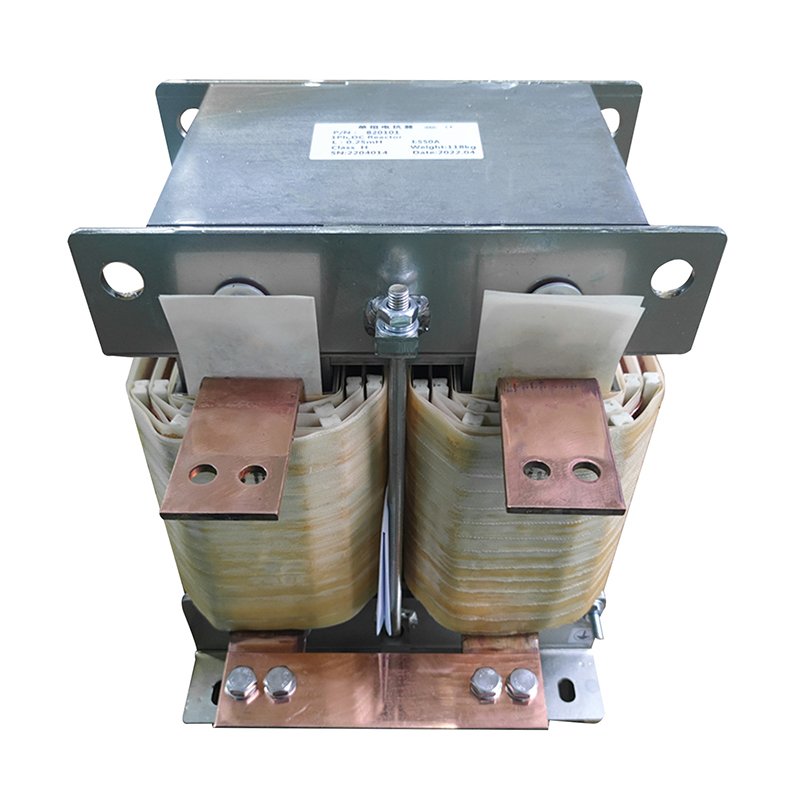

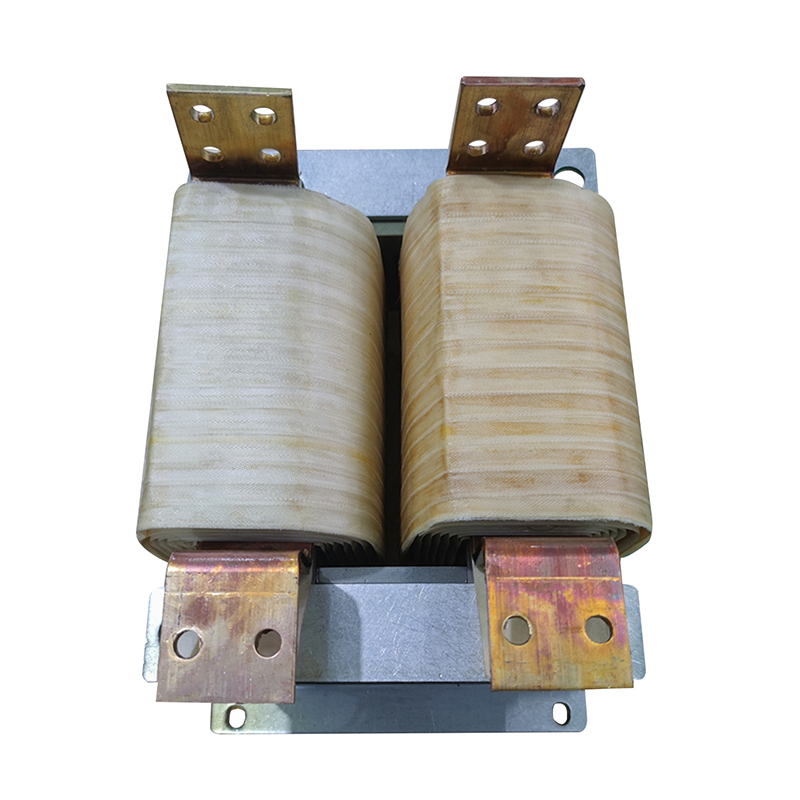

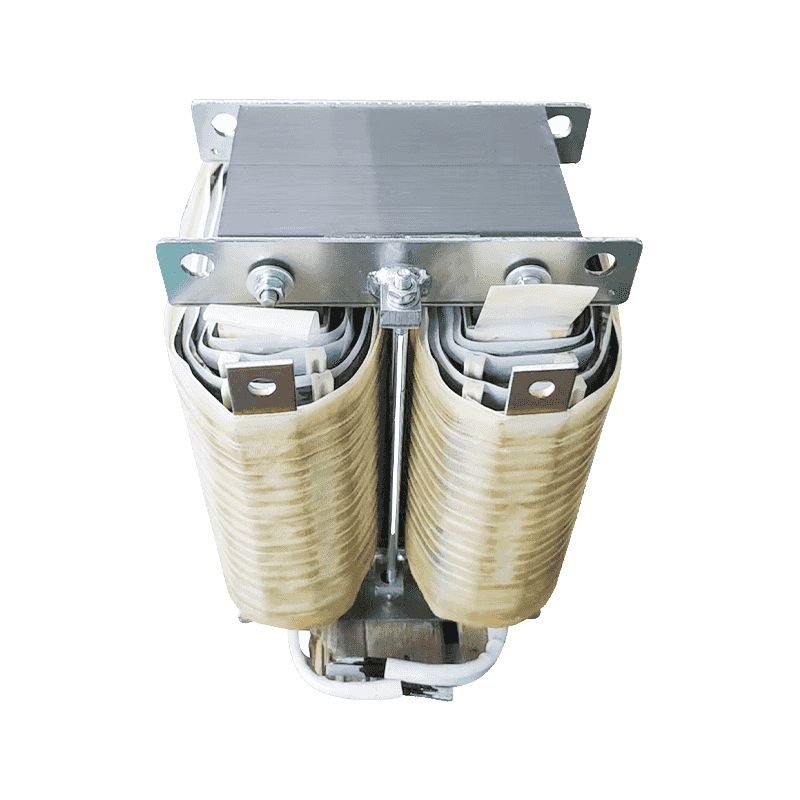

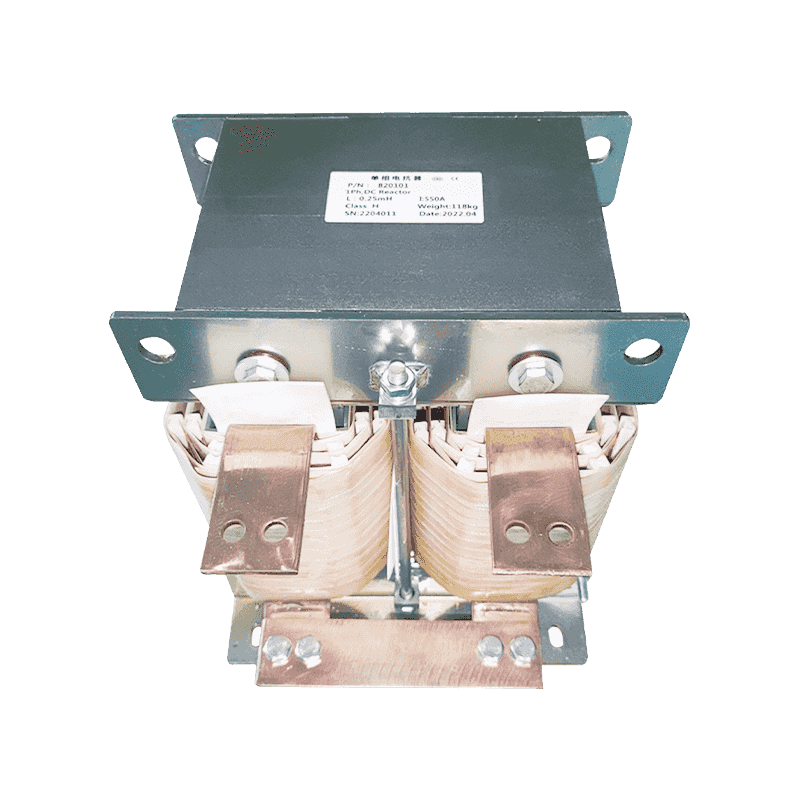

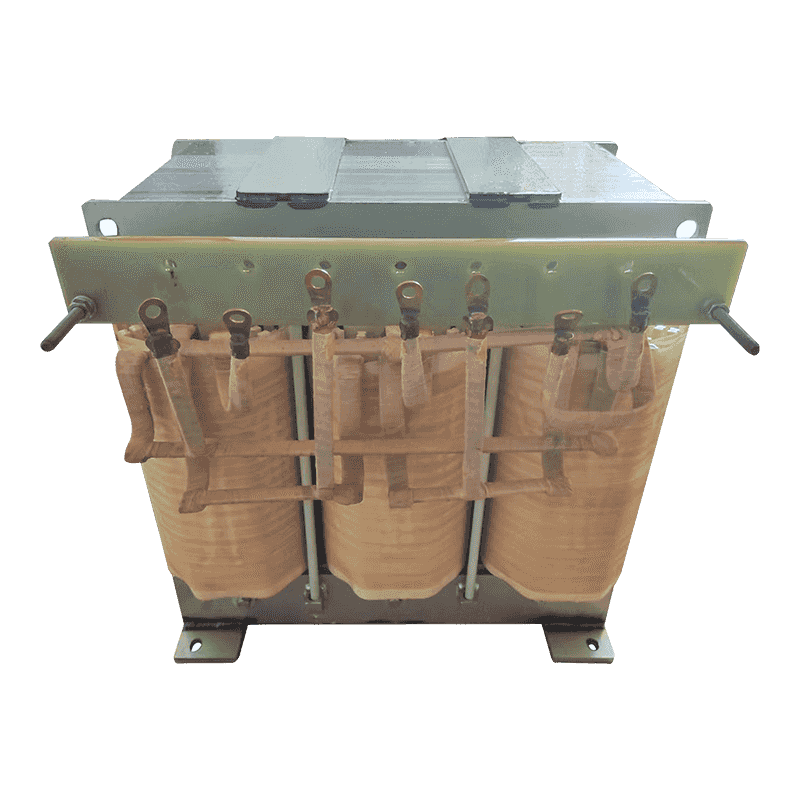

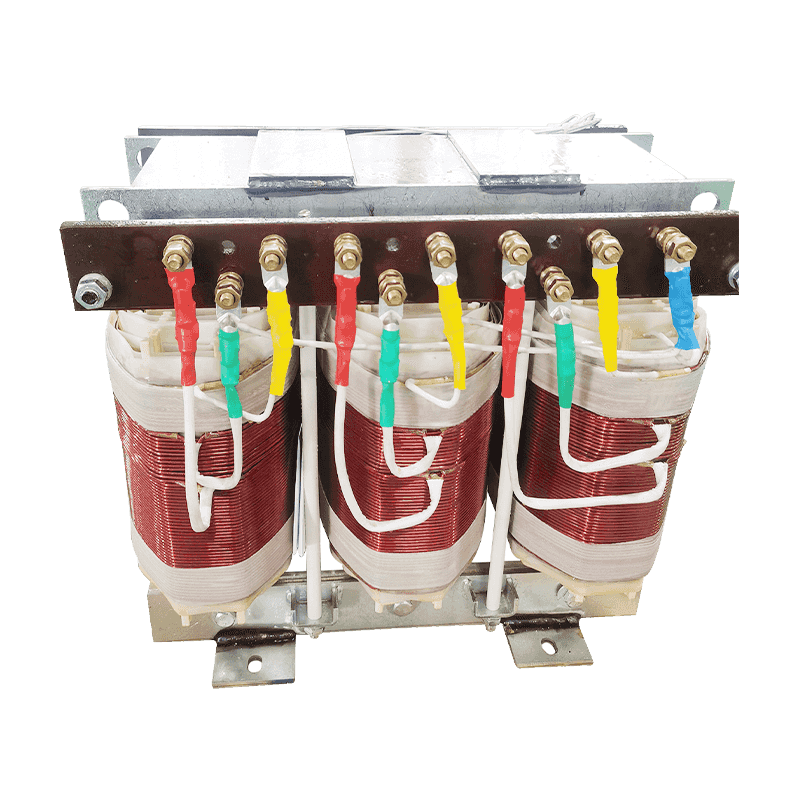

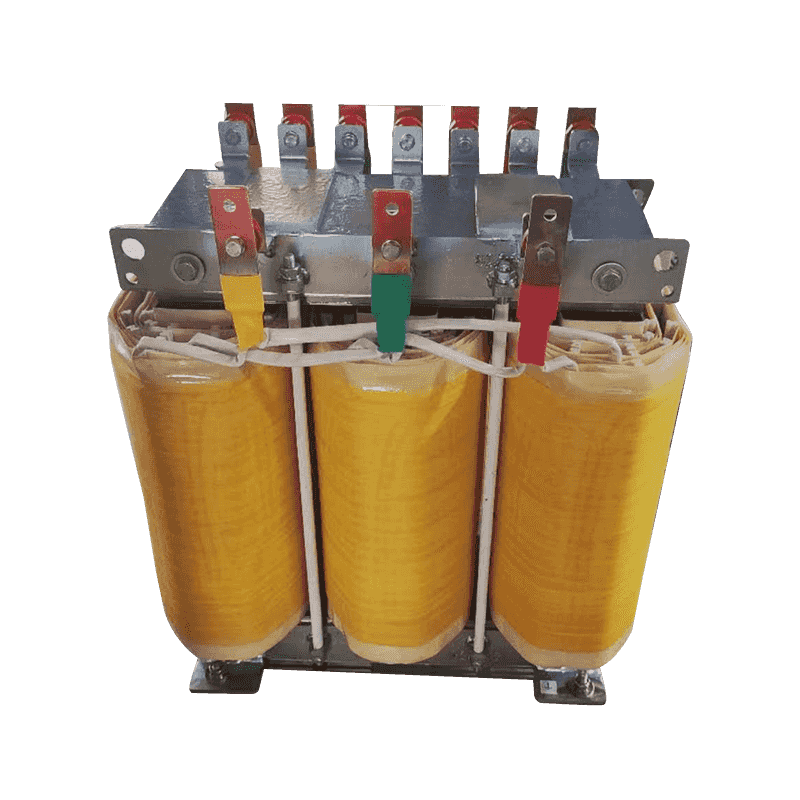

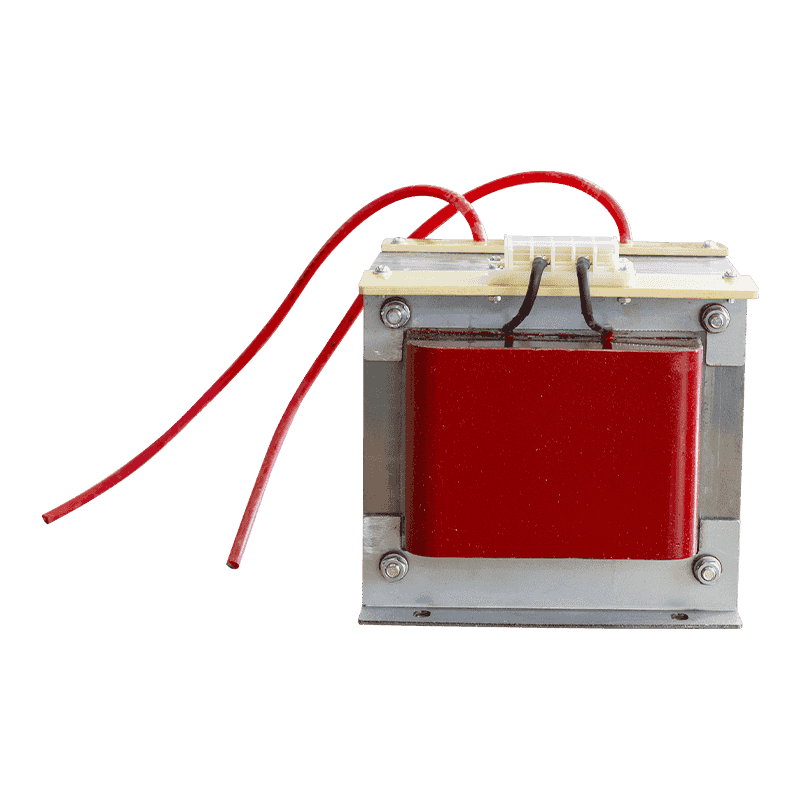

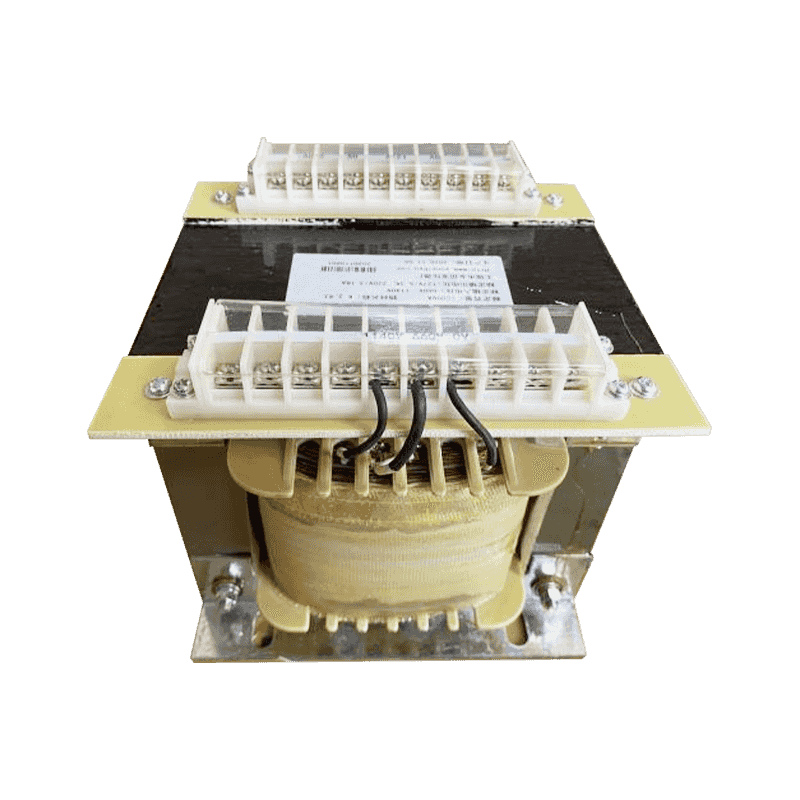

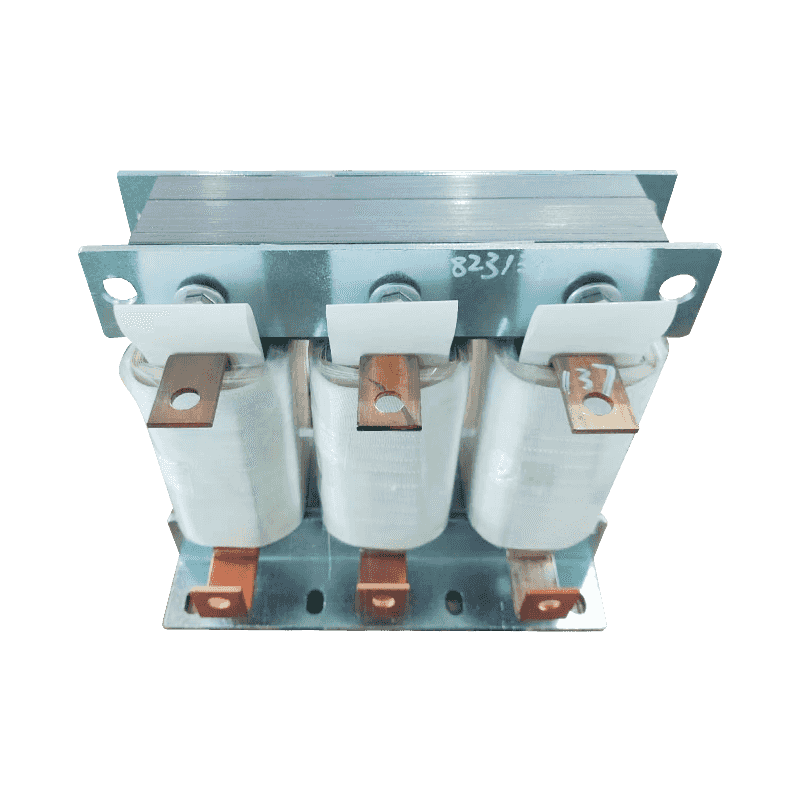

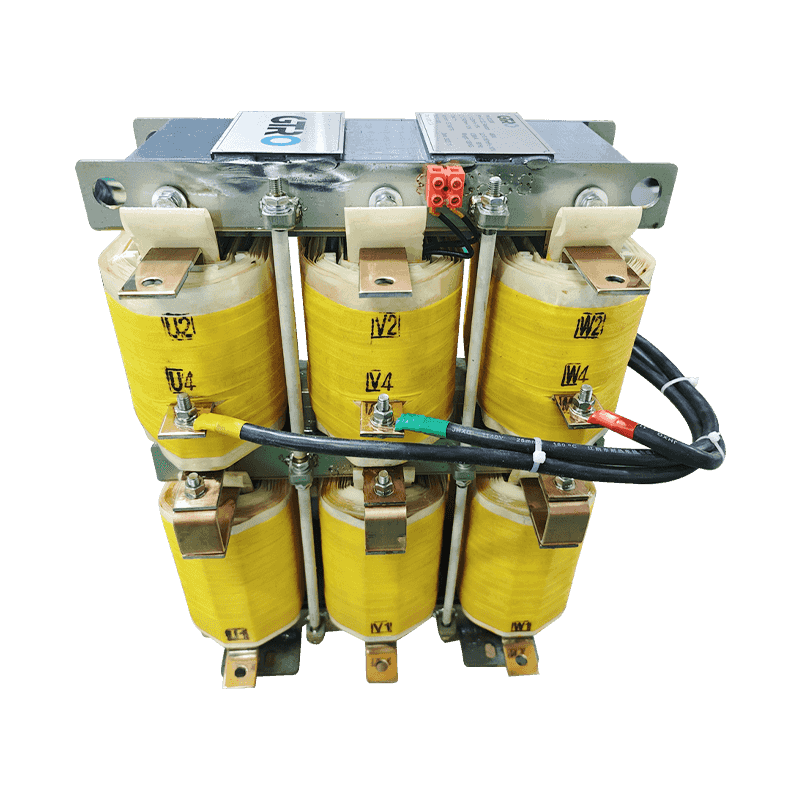

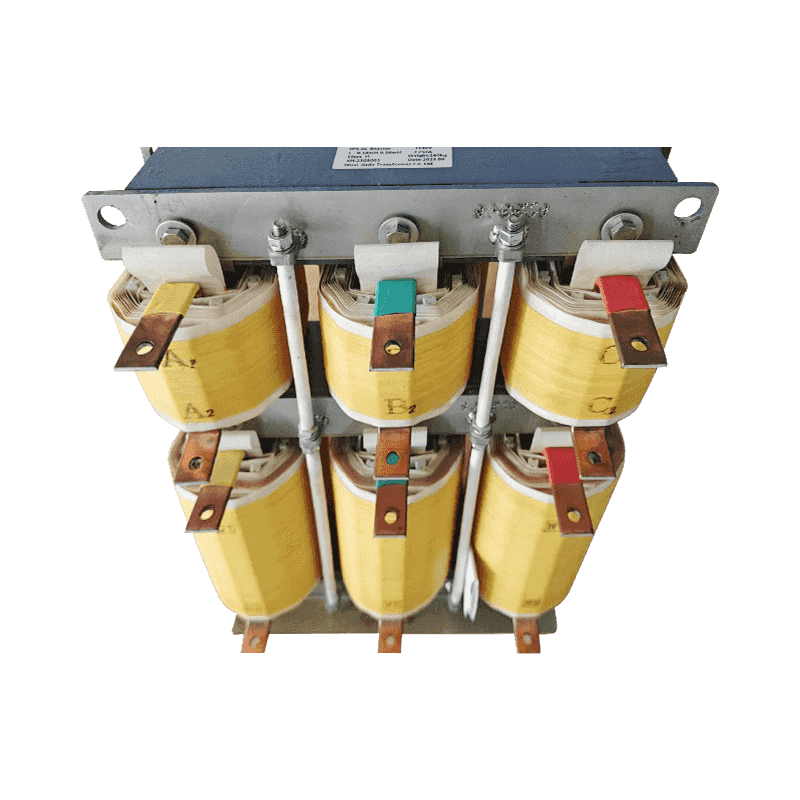

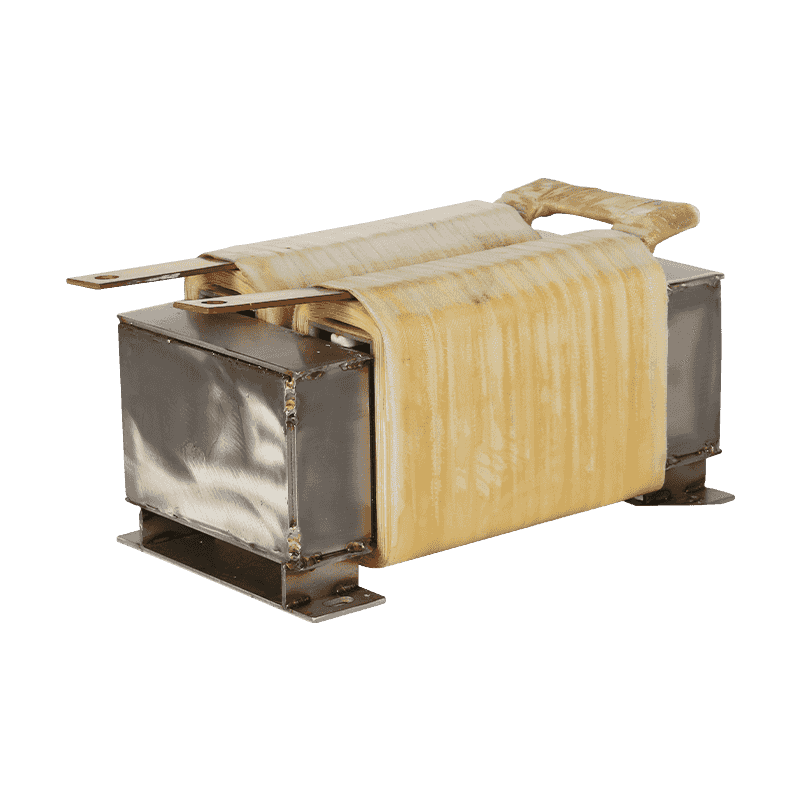

1 The core is made of a high-quality low-loss cold rolled silicon steel sheet. The column is divided into small uniform segments by multiple air gaps. The air gap is spaced by epoxy laminated glass cloth boards and coated with special adhesive to ensure that the reactance air gap does not change during operation and is noiseless;

2. The coil is wound with F or H-grade enameled copper flat wire, which is tightly and uniformly arranged, without an insulation layer on the outside. Small-capacity coil adopts layer structure, while large-capacity coil adopts cake structure, which has better ventilation and heat dissipation effect;

3. The DC reactor coil and core are assembled into one piece and then go through the process of pre-drying-vacuum impregnation paint-hot drying and curing. The use of Class H impregnating varnish makes the coils and cores of Satons reactors firmly bonded together. This greatly reduces noise during operation and has a very high heat resistance rating, which ensures that the reactor can be operated noiselessly and safely even at high temperatures;

4. The DC reactor core column fasteners are made of non-magnetic materials to ensure the reactor has a low-temperature rise;

5. The exposed parts are treated with anti-corrosion treatment; the lead-in terminals are made of tin-plated copper tube terminals or copper rows.

| Inductance | 0.17 mH ±10% |

| Rated Voltage | 680V |

| Rated Current | 320A |

| Phase | 1PH |

| Frequency | 50/60Hz |

| Conductor material | Copper |

| Temperature rise | ≤ 65K |

| Noise | <70dB@1m |

| Isolation Class | H class |

| Cooling month | AN |

Eng

Eng  Español

Español