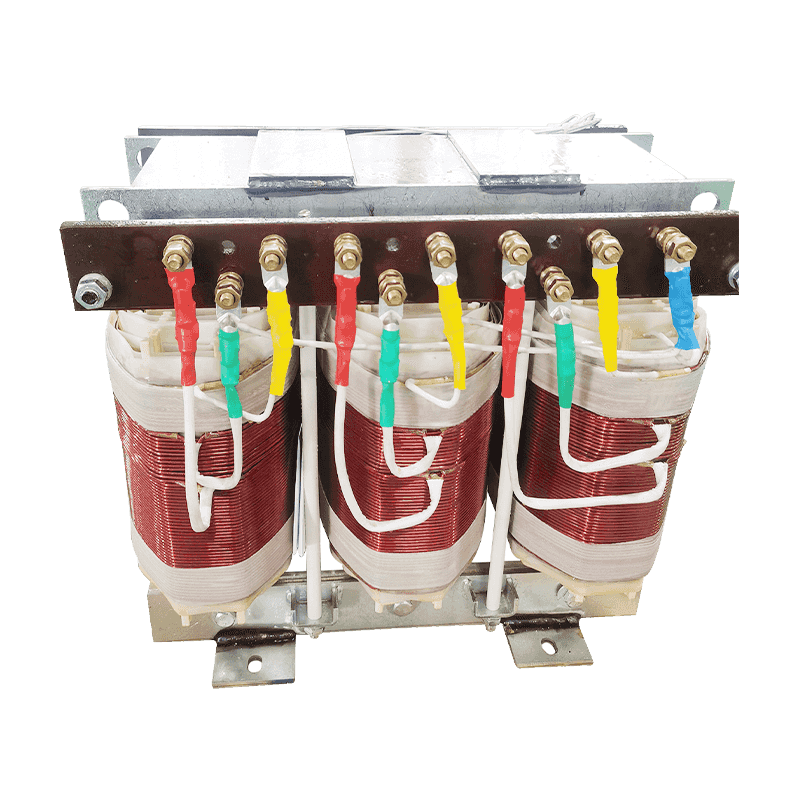

30KVA AL wire 230V to 480V 3PH Dry-type Transformer

Cat:Three Phase transformer

A three-phase transformer is a type of power transformer used to convert voltage from one three-phase circuit to another. They are widely used in powe...

See Details

In the power system, autotransformers are key equipment for voltage conversion and energy transmission, and the stability and safety of their performance are crucial. The basis of all this is inseparable from the careful selection and treatment of insulation materials. The selection of insulation materials is the first step in the insulation treatment of autotransformers and a key factor in determining their overall performance.

Insulation materials play a vital role in autotransformers. They not only determine the electrical insulation performance of the transformer, but also directly affect its mechanical strength, heat resistance and long-term operation reliability. Choosing suitable insulation materials can effectively prevent faults such as current leakage, voltage breakdown and short circuit, thereby ensuring the stable operation of the transformer in a complex and changeable power environment.

Autotransformers usually use high-performance insulation paper, insulation paint or insulation oil as insulation media. These materials have become the first choice for transformer insulation treatment due to their excellent electrical insulation performance and mechanical strength.

Insulation paper is one of the most commonly used insulation materials in autotransformers. It has good electrical insulation performance and mechanical strength, and can withstand high voltage and high temperature environments. At the same time, insulation paper also has good moisture absorption and air permeability, which helps to reduce partial discharge and overheating of the transformer. In the manufacturing process of autotransformers, insulating paper is often used in coil winding, interlayer insulation and end insulation to ensure electrical isolation and mechanical support between coils.

Insulating varnish is a liquid insulating medium coated on the surface of insulating materials. It has good electrical insulation and heat resistance, and can effectively prevent current leakage and voltage breakdown. In the manufacturing process of autotransformers, insulating varnish is often used for impregnation and curing of coils to improve the electrical insulation and mechanical strength of coils. At the same time, insulating varnish can also play a role in moisture-proof, mildew-proof and corrosion-proof, extending the service life of the transformer.

Insulating oil is another important insulating material in autotransformers. It has good electrical insulation and heat dissipation properties, and can effectively reduce the temperature rise and partial discharge of the transformer. In the operation of the autotransformer, insulating oil can also play a role in lubrication and cooling, reduce friction and wear, and improve the operating efficiency of the transformer. At the same time, insulating oil can also absorb and neutralize the free charge inside the transformer to prevent voltage breakdown and discharge.

When selecting the insulation material of the autotransformer, it is necessary to comprehensively consider its electrical insulation performance, mechanical strength, heat resistance, moisture resistance and cost. The following is a detailed discussion of these performance characteristics and selection principles:

Electrical insulation performance: The electrical insulation performance of the insulation material is the key to ensure that it can prevent current leakage and voltage breakdown. Therefore, when selecting insulation materials, it is necessary to give priority to its electrical performance indicators such as dielectric constant, dielectric loss, and breakdown voltage.

Mechanical strength: The autotransformer will be subjected to various mechanical stresses during operation, such as vibration, impact, and tension. Therefore, the insulation material needs to have good mechanical strength to withstand the effects of these stresses and prevent the insulation layer from cracking and falling off.

Heat resistance: The autotransformer will generate a lot of heat during operation, causing the temperature to rise. Therefore, the insulation material needs to have good heat resistance and be able to maintain stable electrical insulation performance and mechanical strength in a high temperature environment.

Moisture resistance: In a humid environment, the insulation material easily absorbs moisture, resulting in a decrease in electrical insulation performance. Therefore, when selecting insulation materials, it is necessary to consider its moisture resistance to ensure that good electrical insulation performance can still be maintained in a humid environment.

Cost: The cost of insulating materials is also one of the factors that need to be considered when selecting. Under the premise of ensuring performance, materials with lower costs should be selected as much as possible to reduce the manufacturing cost of the transformer.

In the manufacturing and operation of autotransformers, the application and safeguard measures of insulating materials are crucial. The following is a detailed discussion of these measures:

Careful selection and testing: When selecting insulating materials, strict testing and screening are required to ensure that their performance meets the design requirements. At the same time, the production process of the material needs to be monitored to ensure its stable and reliable quality.

Reasonable design and manufacturing: In the design process of the autotransformer, it is necessary to make a reasonable design based on the performance characteristics of the insulating material, such as the winding method of the coil, the thickness and number of layers of the insulating layer, etc. In the manufacturing process, the process parameters need to be strictly controlled to ensure the uniformity and integrity of the insulating layer.

Regular inspection and maintenance: In the operation of the autotransformer, the insulating material needs to be inspected and maintained regularly, such as measuring insulation resistance, detecting partial discharge and temperature rise. Once the insulation performance is found to be degraded or a fault occurs, measures should be taken in time to repair or replace it.

Safety protection measures: During the operation and maintenance of the autotransformer, necessary safety protection measures need to be taken, such as setting up grounding devices, installing protective covers and warning signs, etc., to prevent electric shock and equipment damage.

The selection and processing of insulating materials are key links in the manufacturing and operation of autotransformers. Through careful selection and testing, reasonable design and manufacturing, regular inspection and maintenance, and the implementation of safety protection measures, the stability and safety of autotransformers in long-term operation can be ensured. In the future, with the continuous advancement of power technology and the rapid development of new energy, the insulation materials and technologies of autotransformers will continue to innovate and improve, providing more reliable guarantees for the stable operation of the power system. We should also continue to pay attention to the research and development trends of insulating materials, and contribute more wisdom and strength to the performance improvement and cost reduction of autotransformers.

Contact Us